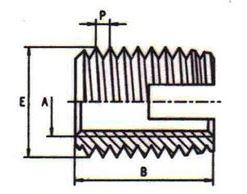

Thin Walled Threaded Inserts SELF-TAPPING DIMENTIONS Ensat ® Works Standard 303/347/348

Thin Walled Threaded Inserts

SELF-TAPPING DIMENTIONS

Ensat ® Works Standard 303/347/348

The ENSAT® 302 series is designed to provide maximum pull-out strenght and wear

resistent threads in plastics, metals and hardwood. A lead-in cutting slot provides for an

easy self tapping installation and the resulting connection is highly resistant to vibration.

Use in: light metal alloys, cast iron, brass, bronze, NF metals, plastics, laminated materials, hardwoods

Description of a self-cutting threaded insert, works standard 302 with internal thread A=M5, in steel, hardened, zinc plated and

yellow chromated

Article No n’ | Internal Thread A | External Thread | Length B | Recommended hole diameter | Minimum hole depth (blind bores) | ||

| E | P | Weak metal alloys L | brittle metal alloys L | ||||

| 303 0 040 | M 4 | 6 | 0.7 | 6 | 5.5 to 5.6 | 5.6 to 5.7 | 8 |

| 303 0 050 | M 5 | 7 | 0.8 | 8 | 6.5 to 6.6 | 6.6 to 6.7 | 10 |

| 303 0 060 | M 6 | 8 | 1.0 | 10 | 7.3 to 7.4 | 7.5 to 7.6 | 13 |

| 303 0 080 | M 8 | 10 | 1.25 | 12 | 9.0 to 9.2 | 9.0 to 9.4 | 15 |

| 303 0 100 | M 10 | 12 | 1.5 | 15 | 11.0 to 11.2 | 11.2 to 11.4 | 18 |

Material, tolerances, threads: Works standard 303

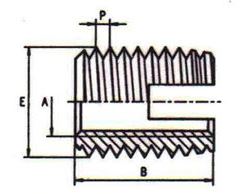

Works Standard 347: Short size, Works Standard 348: regular length

Article No n’ | Internal Thread A | External Thread | Length B Works standard | Recommended hole diameter for metal alloys NF-Metals L | Minimum hole depth (blind holes) T Works Standard | |||

| E | P | 347 | 248 | 347 | 348 | |||

| 3. 0 040 | M 4 | 6 | 0.7 | 6 | 8 | 5.4 to 5.6 | 8 | 10 |

| 3. 0 050 | M 5 | 6.5 | 0.8 | 7 | 10 | 6.0. to 6.2 | 9 | 13 |

| 3. 0 060 | M 6 | 8 | 1 | 8 | 12 | 7.5 to 7.7 | 10 | 15 |

| 3. 0 080 | M 8 | 10 | 1.25 | 9 | 14 | 9.4 to 9.6 | 11 | 17 |

| 3. 0 100 | M 10 | 12 | 1.5 | 10 | 18 | 11.2 to 11.5 | 13 | 22 |

| 3. 0 120 | M 12 | 14 | 1.75 | 12 | 22 | 13.2 to 13.5 | 15 | 26 |

| 3. 0 140 | M 14 | 16 | 2 | 14 | 24 | 15.1 to 15.4 | 17 | 28 |

| 3. 0 140 | M 16 | 18 | 2 | 14 | 24 | 17.0 to 17.4 | 17 | 28 |

Material, tolerances, threads: Works standard 307/308